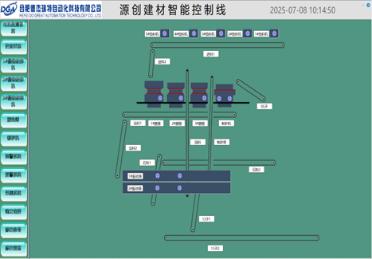

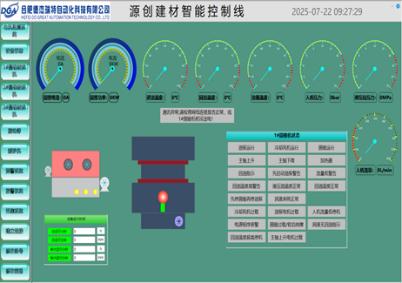

Intelligent control system for source material creation

This system takes full-chain equipment management as its core and builds a complete system of "digital foundation, networked linkage, and intelligent upgrade" through multi-module collaboration.

At the digital level, it relies on real-time monitoring functions to accurately collect and dynamically present key status data such as equipment current, pressure, and temperature, establishing a comprehensive digital profile for the equipment and achieving a deep mapping from physical equipment to digital twins. At the networked level, it uses the data cloud and platform function to open up data transmission channels, seamlessly connecting equipment data to the cloud platform through standardized interfaces, breaking down information silos, and building an interconnection network between equipment and the platform, as well as between the platform and managers, making data flow more efficient and management more coordinated. At the intelligent level, on the one hand, it uses the early warning system to intelligently analyze equipment operation data, identify potential fault risks in advance, and give staff a time window for proactive intervention; on the other hand, it relies on the alarm system to quickly locate problem nodes when equipment malfunctions occur, shorten the fault detection and resolution cycle, and shift from "reactive response" to "proactive prevention", comprehensively enhancing the intelligent level of production and manufacturing. In addition, the permission management module ensures operational norms and system security through refined functional permission division, providing a guarantee for the stable operation of the entire system. Ultimately, the system, with digitalization as the foundation, networking as the link, and intelligence as the goal, realizes the transformation of equipment management from the traditional mode to a modern mode that is efficient, precise, and intelligent.