Self-stabilizing vertical lifting system:

It is renowned for its extremely strong self-stability. In scenarios with heavy loads and variable loads, it can dynamically adjust the lifting parameters. When the load offset is within ±5mm, it can quickly and automatically correct the deviation, ensuring a vertical accuracy error of less than 0.2% throughout the lifting process. This ensures the safety of precise lifting and operations in hazardous environments.

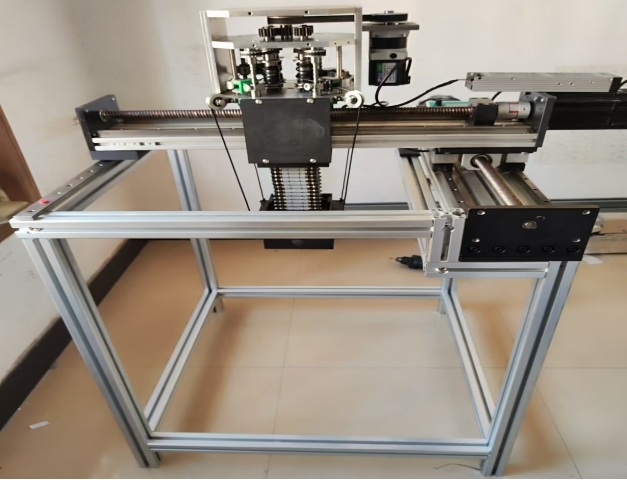

The design is modular, integrating servo motor drive and precise ball screw transmission. The lifting speed supports continuous speed adjustment from 0.1 to 5 meters per minute. It can flexibly adapt to different load weights and large and small factories. The load capacity covers 5 to 500 kg, and the lifting stroke can reach 0.5 to 3 meters. The lifting response is fast and the operation is smooth, enabling efficient completion of vertical lifting tasks. At the same time, it supports intelligent remote control and automation integration, integrating into the industrial Internet of Things to achieve real-time data interaction and remote operation, helping to build smart factories and advancing the transformation of lifting operations from "man-to-man supervision" to "intelligent collaboration".

The aluminum alloy frame is combined with high-precision components, balancing structural strength and lightweight. Installation is convenient, and it occupies a small area. It is suitable for various site layouts. Key components have undergone rigorous testing and optimization, being wear-resistant and fatigue-resistant, with a service life far exceeding that of competitors. The operation and maintenance costs are low, providing a stable, efficient, and intelligent vertical lifting solution for research and experimentation, industrial production, and other scenarios, leading the new revolution in lifting operations.