Intelligent Logistics Management System

Based on the core framework of "front-end and back-end collaboration, technology empowerment and efficiency", an intelligent management system covering the entire logistics process has been constructed. The back-end serves as the "nerve center" for data interaction, deeply integrating various nodes such as equipment PLC, secondary systems, third-level/MES/ERP systems, cranes, and PDAs. Through seamless data flow and real-time information synchronization, it breaks the information barriers in traditional logistics processes, forming a full-chain data loop from the control of underlying equipment to the management decisions at the upper level - providing precise and dynamic basic data support for front-end applications, and simultaneously synchronizing the operation information and performance data fed back by the front end to each related system in reverse, achieving the collaborative linkage of equipment operation, production scheduling, and resource allocation during the logistics process.

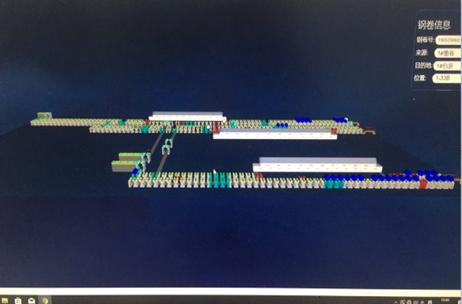

The front-end focuses on user operation and management requirements, integrating core functions such as steel coil tracking, steel coil information management, information query, report analysis, and permission management: The steel coil tracking function enables visualized traceability of the entire logistics process, real-time positioning of the steel coil's location and status; the steel coil information management module integrates key data such as specifications, batches, and destinations, providing a basis for scheduling decisions; the information query and report functions present data through aggregation and visualization, allowing managers to quickly grasp core indicators such as logistics efficiency and resource utilization rate; the permission management ensures operational norms and data security through refined functional division.

The system is driven by technological innovation, with embedded AI scheduling algorithms like a "smart brain", conducting intelligent analysis of logistics paths, equipment loads, and task priorities to optimize key links such as crane scheduling and transportation sequencing, achieving dynamic optimization of resource allocation; combined with the popular PDA terminals, management functions are extended to the operation site, allowing operators to collect and upload data through mobile devices, breaking the limitations of fixed office scenarios and enhancing operational flexibility and response speed.

Overall, this system uses the convenient application of the front end as the tentacles, the data collaboration of the back end as the foundation, and AI algorithms and mobile technology as the engine, constructing an "perception - analysis - decision - execution" intelligent logistics management loop. It not only improves the tracking accuracy and scheduling efficiency of steel coil logistics, but also promotes the transformation of logistics management from "experience-driven" to "data-driven", providing solid support for enterprises to reduce costs, increase efficiency, and upgrade intelligence.