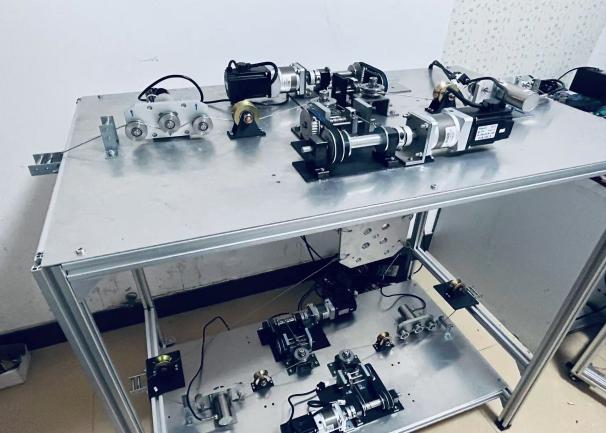

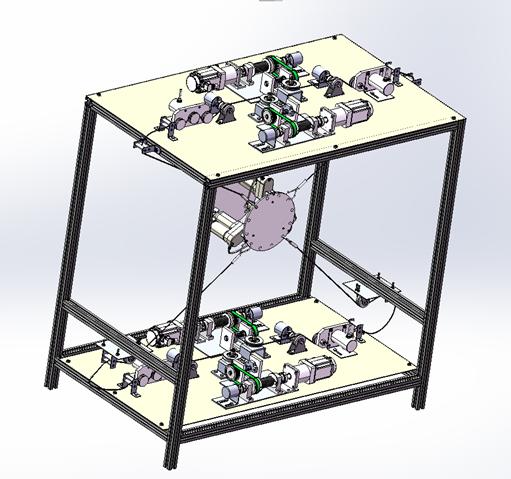

Rope-driven parallel robot:

The rope-driven parallel robot uses flexible ropes instead of traditional rigid links. By coordinating multiple motors to control the length of the ropes, it enables precise movement of the end effector in three-dimensional space. Its core features and advantages are as follows:

1. Significant technical advantages

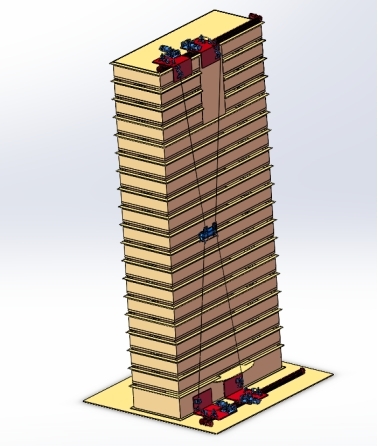

Super large workspace: The flexible nature of the ropes allows for a movement range of tens of meters, making it suitable for large-scale scenarios such as wind tunnel experiments and spacecraft docking simulations.

High dynamic response: The lightweight design combined with low-inertia drives enables an acceleration of over 10 m/s², making it suitable for high-speed pick-and-place and trajectory tracking tasks.

Load adaptability: Through tension optimization algorithms, the rope tension can be dynamically adjusted to accommodate load requirements ranging from grams to hundreds of kilograms.

2. Key performance parameters

Accuracy: Repeatability positioning accuracy of ±0.1 mm (in local workspace), and absolute accuracy of ±1 mm with visual/laser assistance.

Degrees of freedom: Supports 3-6 degrees of freedom, with a typical configuration of 6 degrees of freedom (3 translations + 3 rotations).

Expandability: The modular design supports multi-machine collaboration, suitable for complex tasks such as large-scale surface processing.

3. Application scenarios

It covers various fields including industrial sorting, aviation simulation, medical rehabilitation, and special operations, especially suitable for large-scale and highly flexible operation requirements. The system performance can be continuously improved through innovative control algorithms (such as anti-interference robust control and intelligent optimization), contributing to the development of advanced equipment.